What is Flexible packaging? Types and Applications

In the modern consumer market, flexible packaging has become a critical player in protecting products and attracting customers. From food and beverages to cosmetics and medical supplies, its lightweight, space-saving, and highly protective features have led to its increasingly widespread use.

This article will provide a deep dive into the fundamental concepts, core advantages, primary types, and future trends of flexible packaging, offering you a comprehensive understanding of this innovative packaging solution.

What is Flexible Packaging?

Flexible packaging is a modern, non-rigid form of packaging, commonly seen as pouches, films, and sachets. It is primarily constructed from pliable materials like paper, plastic films, and aluminum foil, often in multi-layered laminated structures to enhance its barrier properties and functionality. Compared to rigid packaging such as glass jars or metal cans, flexible packaging offers superior advantages in design versatility, transportation efficiency, and user convenience.

The Five Core Advantages of Flexible Packaging

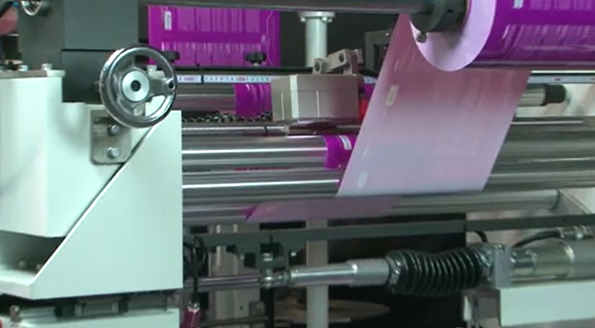

▲Flexible packaging is essential for protecting

products and attracting customers.

● Ultimate Space Efficiency

Flexible packaging can be stacked or compressed, significantly reducing the space required for warehousing and transportation, which directly lowers logistics costs. Its product-conforming nature also minimizes unnecessary packaging waste, aligning with modern retail demands for compact packaging.

● Extended Product Shelf Life

Through specialized barrier layers, flexible packaging effectively protects against moisture, oxygen, light, and odors. This locks in product freshness and flavor, significantly extending shelf life. Its durable and puncture-resistant qualities also reduce the risk of product damage during transportation and storage.

● Lower Costs and Higher Production Efficiency

The lightweight nature of flexible packaging materials not only saves on transportation costs but also results in relatively lower production costs. Materials supplied in roll stock form can be used with automated Form-Fill-Seal (FFS) equipment for highly efficient production, a key to high-volume packaging operations.

● High Customization and Design Flexibility

Flexible packaging offers exceptional design freedom, allowing for customization into various sizes and shapes. It supports high-quality printing techniques, enabling brands to create eye-catching visual designs and even stand out on the shelf with unique shapes and textures.

● Superior User Experience

Lightweight and durable, flexible packaging is ideal for on-the-go consumption, meeting the demands of modern consumer lifestyles. Many packages also integrate convenient features like easy-tear notches, resealable zippers, or spouts, enhancing product usability and boosting consumer brand affinity.

Common Types of Flexible Packaging

Flexible packaging comes in numerous forms, allowing businesses to select the most suitable type for their products:

● Stand-Up Pouches: Feature a bottom gusset that allows them to stand securely on shelves, making them a popular choice for snacks, grains, and liquid products.

● Pillow Pouches: The most economical and simple pouch type, commonly used for single-serving snacks like cookies and chips.

● Flat Bottom Pouches: Offer five printable panels and a stable flat base, favored by industries such as coffee beans and pet food.

● Spouted/Shaped Pouches: Equipped with a spout for easy pouring of liquids or designed in unique shapes to enhance brand recognition.

● Gusseted Pouches: Have expandable side or bottom gussets to increase volume, suitable for larger-capacity products.

● Retort Pouches: Specifically designed to withstand high-temperature sterilization, allowing for long-term food preservation without refrigeration.

● Stick Packs: Slender, tube-shaped packs ideal for single servings of powders or granules, such as instant coffee or sugar.

● Roll Stock: Packaging material delivered in a roll for clients to use with their in-house automated packaging machinery.

The Manufacturing Process of Flexible Packaging

The production of flexible packaging is a process that blends art with precision engineering. It can be refined into three core stages, each critical to the final product's quality, functionality, and visual appeal.

Stage 1: Pre-press and Printing

This stage begins with package design, plate-making, and printing. Using advanced technology and strict color management, sophisticated designs are accurately printed onto the flexible material, laying a perfect foundation for subsequent steps.

Stage 2: Material Converting and Roll Preparation

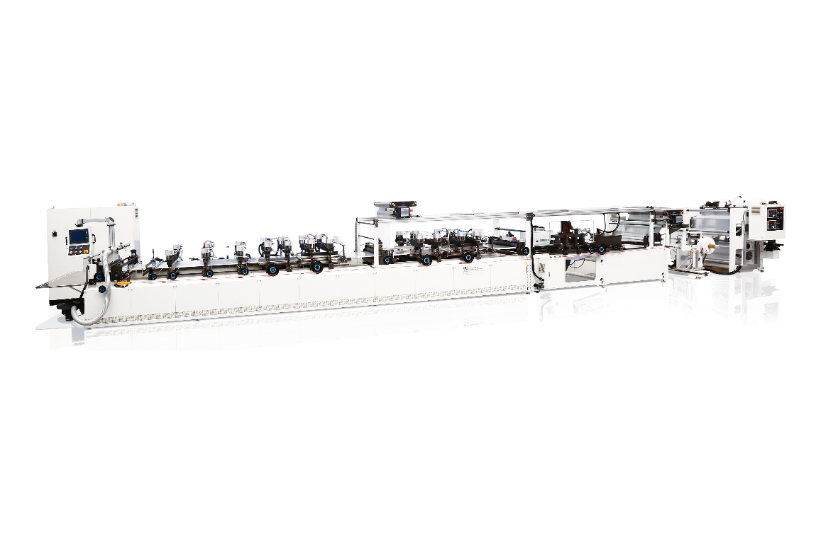

After printing and lamination, the material enters the critical converting phase. This is where Dah Bah Machinery’s expertise ensures optimal roll quality for downstream efficiency. Our precision Slitting Machines cut master rolls to exact widths, while our Roll Rewinding & Inspecting Machines guarantee that each roll is perfectly tensioned, aligned, and defect-free. For applications requiring pre-cut materials, our Cutting/Sheeting Machines provide precise and consistent results, preparing the material perfectly for the final stage.

Stage 3: Pouch Forming and Finishing

In the final stage, the prepared roll is transformed into a finished product. This is the core function of Dah Bah’s versatile Bag Making Machines which form and seal the primary pouch.

Beyond basic forming, Dah Bah offers a complete suite of finishing solutions to add value and functionality. Our specialized equipment enhances the final package with:

● Spout Inserting & Sealing Machines for liquid and pourable products.

● Embossing Machines to add unique textures and branding elements.

● Shrinkable / Label Packaging Machines for secondary packaging and labeling.

● A variety of other Sealing Machines to meet specific functional requirements.

Applications of Flexible Packaging

● Food Industry: From snacks and frozen foods to ready-to-eat meals, the superior barrier properties of flexible packaging are key to maintaining freshness.

● Beverage Industry: Spouted pouches have become a lightweight alternative for juices, soups, and dairy products.

● Cosmetics & Personal Care: Small, portable sachets and sample packs effectively protect sensitive formulas such as lotions and face masks.

● Household Goods: Refill packs for products like laundry detergent and hand soap are not only convenient but also help reduce plastic waste.

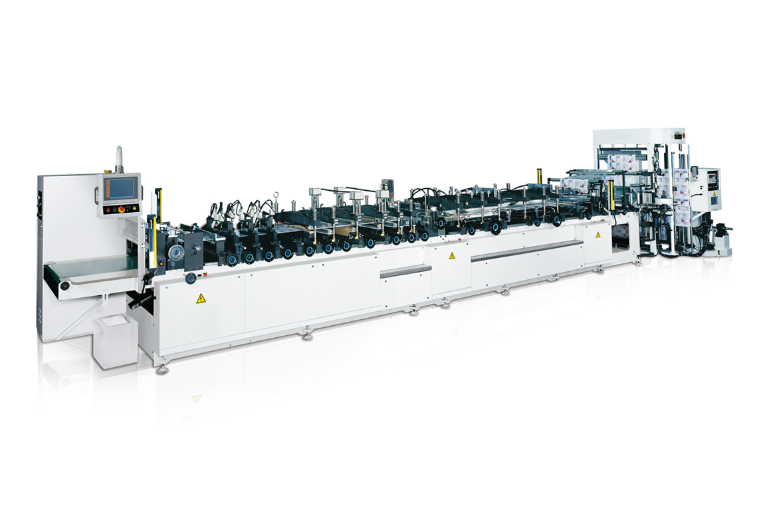

● Medical & Pharmaceutical: Flexible packaging provides sterile, moisture-proof protection, ensuring the efficacy and safety of medical devices and drugs. For high-standard medical packaging needs, specialized equipment like Dah Bah's AMM-83F medical bag making machine provides reliable and precise solutions.

● Electronics & Technology Industry: Semiconductor wafers, precision components, and electronic devices require packaging with advanced protective features. Anti-static bags, vacuum-sealed pouches, and moisture-barrier bags are commonly used to safeguard products from static discharge, humidity, and contamination during transportation and storage. These specialized flexible packaging solutions are often produced in high-cleanliness environments and meet rigorous international standards, ensuring both product integrity and reliability in demanding technology applications.

▲Dah Bah’s AMM-83F medical bag making machine

Future Trends in Flexible Packaging: Sustainability and Innovation

The future of flexible packaging is heading in two main directions:

● Sustainability: Recyclable, mono-material solutions (e.g., PE or PCR) are set to become mainstream. Practices like "right-sizing" to reduce waste and promoting refillable packaging models will collectively lower the environmental footprint.

● Deeper Applications in Medical & Biotech: With the rise of home healthcare, flexible packaging that ensures sterility, is tamper-evident, and is easy to use will play an even more crucial role. This will increase the importance of machines that can produce high-standard, professional medical bags, such as Dah Bah's medical bag making machines.

FAQ

Q1: How does Dah Bah's equipment help clients produce their ideal bag types?

Dah Bah Machinery ensures equipment can precisely manufacture our clients' desired bag formats through two core strengths:

- Deep Customization and Engineering Capabilities: With extensive experience accumulated since 1964, we provide tailored equipment solutions based on our clients' specific bag requirements (e.g., stand-up, zipper, medical bags) and material characteristics.

- Advanced Technology Integration: Our machines are equipped with servo motor-driven systems, advanced tension control, and precise alignment and sealing technologies. These features guarantee accurate pouch dimensions, superior seal quality, and reduced material waste, enabling highly efficient production. Our entire equipment range complies with international standards such as ISO 9001 and CE, offering clients the most reliable quality assurance.

Q2: What are the common materials used in flexible packaging?

The choice of materials depends on the product's protection needs and typically consists of a multi-layer laminated structure of the following key materials:

● Plastic Films: The core components. Polyethylene (PE) is mainly used for the sealing layer; Polypropylene (PP) provides strength and barrier properties; and Polyester (PET) is often used for the printing layer, offering rigidity and gloss.

● Aluminum Foil: Provides top-tier barrier performance, effectively blocking light, oxygen, and moisture. It is ideal for products requiring the highest level of protection.

● Paper: Materials like Kraft paper are often used to provide structural integrity and a rustic visual appeal, while also being an eco-friendly option. These materials are combined through lamination to leverage their individual strengths, creating a final package that is protective, functional, and visually appealing.

Conclusion

With its high degree of flexibility and functionality, flexible packaging is reshaping industry standards across the board. It is more than just a container; it is a powerful tool for enhancing brand value and the consumer experience.

With over 60 years of professional experience, Dah Bah Machinery Industrial Inc. is your trusted global partner for flexible packaging solutions, serving clients in over 70 countries. We provide customized, end-to-end systems from slitting to spout sealing, supported by comprehensive after-sales service. Our versatile ABM-SPZ bag-making machine, for instance, efficiently produces stand-up and zipper pouches for products like coffee and snacks, enhancing both productivity and quality. Contact us to achieve packaging excellence.