-

-

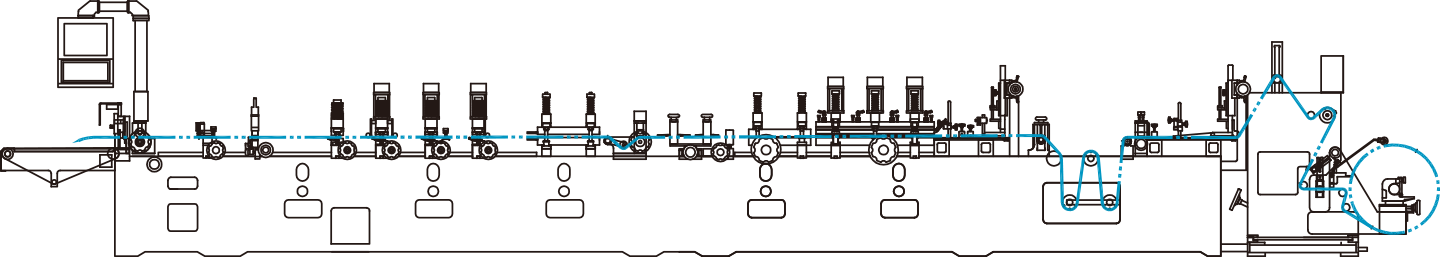

Designed for high performance, reliability, and versatility, Dah Bah’s gusset pouch machine ensures precise, efficient, and user-friendly operation. Let’s examine the key features that make this machine a standout solution for modern packaging applications.

Performance and Reliability

-

Precision and Efficiency

-

Dual material-feeding motors ensure accurate bag length control and high-speed production.

-

Stores up to 100 parameter sets for quick job changes, maintaining consistent quality across different production settings.

-

Seamless Unwinding and Feeding

-

A horizontal unwinder with a movable 3-inch airshaft head simplifies material loading, while automatic tension control ensures smooth feeding and prevents material misalignment.

-

Powerful Main Drive

-

Powered by an AC servomotor and drive system, offering precise control over the sealing process for consistent performance and minimized material waste.

-

Advanced Heat-Sealing Technology

-

Features a high-performance heat-sealing system that delivers strong, uniform seals, even at high speeds.

-

The built-in temperature controller allows precise adjustment via the touchscreen interface, ensuring reliable seals.

-

Automatic sealing head lift during stops prevents overheating, maintaining seal quality.

-

Durability

-

Sealed bearings reduce maintenance requirements and extend machine life, ensuring reliable long-term operation.

Versatility and Usability

-

Versatility

-

Supports both fin-seal and center-seal gusset pouches for flexible packaging options.

-

Handles material thicknesses from 40 to 150 microns, suitable for various applications, including food packaging (e.g. portion packs, microwaveable food, vacuum-sealed tea) and medical uses such as emesis bags.

-

User-Friendly

-

An intuitive touchscreen interface simplifies operation, setup, and monitoring, with direct control over sealing parameters.

-

Safety First

-

Safety features include an automatic sealing head lift, safety cutter, and real-time malfunction alerts to protect the operator and equipment.

These advanced features make Dah Bah’s gusset pouch machine a reliable and flexible tool for any packaging line. Contact us today to learn more!

-

-

Standard Series

| Model No. | ACM-43 | |

|---|---|---|

| Max. Parent Web Width | 820 mm | |

| Max. Parent Web Diameter | 600 mm (Each side) | |

| Center-Seal Bag Width | 50 ~ 400 mm | |

| Gusset-Seal Bag Length | 50 ~ 300 mm | |

| 4-Border-Seal Bag Width | N / A | |

| Max. Gusset Depth | 25 ~ 60 mm (Each side) | |

| Machine Speed | 180 Cuts / min. | |

|

Installation Information (For Standard Specification) |

Net Weight | 3400 kg |

| Area Required | L8700 x W2700 x H2200 (mm) | |

| Power | 380V / 15KW / 287A | |

| Water | 15 - 20 ℃ | |

| Air | 6 kg / cm3 | |

| Various Punching Tools | ||||||

|---|---|---|---|---|---|---|

| Euro-slot | Curve-slot | Butterfly | Slot | Hexagonal | Round | Kidney |

|

|

|

|

|

|

|

Frozen

Tea

Coffee