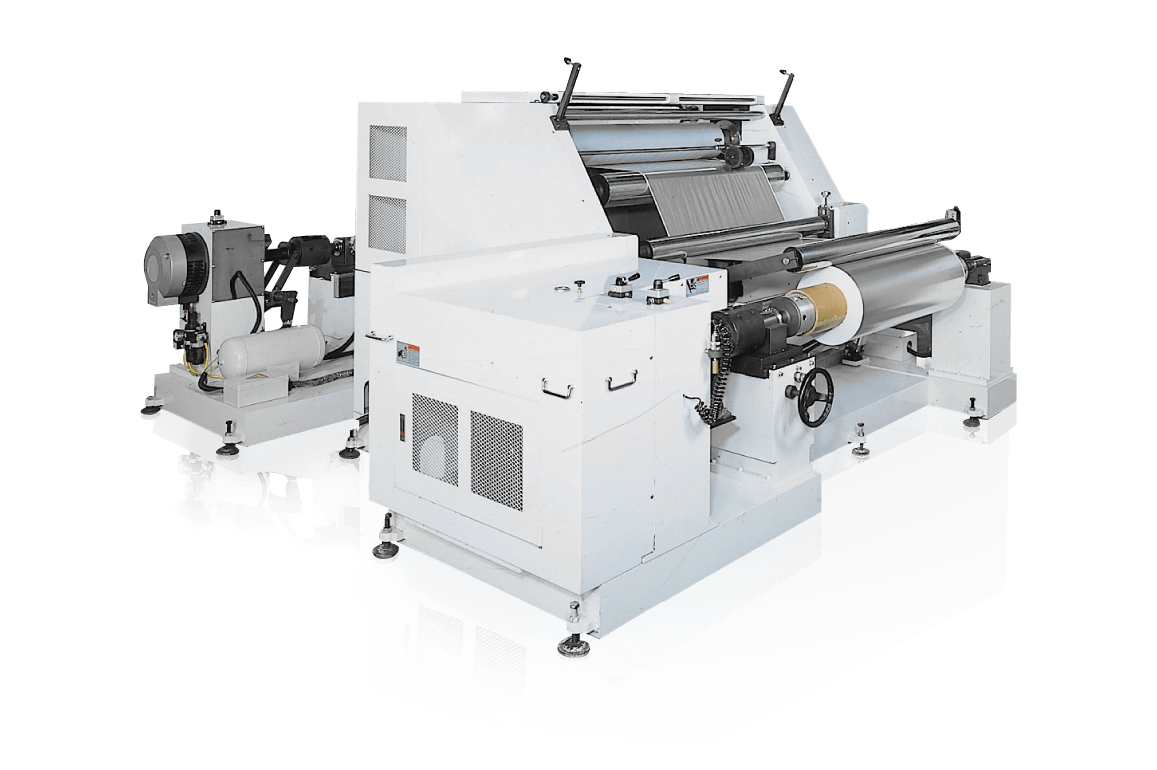

- Application & Materials

-

- Paper laminate, Metalized Paper, Aluminum Foil + Paper

- Rewinding Type

-

- Center rewinding with single rewind shafts.

- Unwinding Section

-

- Equipped with air-shafts (dia.3") making loading and unloading easier.

- Pneumatic unwinding shaft locking device for safety protection.

- Equipped with pneumatic brake as well as electro/pneumatic converter for wide range tension control.

- Unwinding Tension Control

-

- Equipped with automatic tension controller with load-cells. The actual tension is digitally displayed, increasing the tension control precision with minimal operation efforts.

- Embossing Section

-

- Equipped with automatic constant hydraulic pressure control system.

- Individual hydraulic pump with two sets of hydraulic cylinder, ensure the constant embossing-pressure providing.

- Equipped with embossing roller and paper roller.

- Equipped with automatic counter which will stop the machine when reaching pre-set meters.

- Rewinding Section

-

- Equipped with rewind AC induction servomotor to provide constant tension.

- Equipped with rewinding airshaft (dia.6") making loading and unloading easier.

- Rewinding Tension Control

-

- Equipped with automatic tension controller with minimal operation effort.

- Press-roller equipped with constant pressure control system.

- Optional Accessories

-

- Trimming cutter with blower and expulsion tube

- Unwind hydraulic loading device (with shaft)

- Unwind / rewind 3"/6" airshaft

- 6" air chuck

- Shaftless unwind stand (Electrical left/right moving)

- Unwind shaftless hydraulic loading device (Hydraulic up/down, left/right moving)

- Splicing table with suction device

- Shear cutter blade /cutter holder

- Embossing roller / paper roller

| Model No. | REF-B150 | |

|---|---|---|

| Max. parent web width | 1000-1500 mm | |

| Max. parent web diameter | 1000 mm | |

| Thickness rang | Depends on various materials' conditions | |

| Max. rewind diameter | 1000 mm | |

| Unwind/rewind core I.D. | 3" ( Or as request ) | |

| Max. machine speed | 150 M/min. | |

|

Installation information (For 1000mm standard machine) |

Net weight | 3000kg |

| Area required | L 4075 x W 3081 x H 1865 (mm) | |

| Power | As request | |

| Water | X | |

| Air | 6kg/cm3 | |