- Application & Materials

-

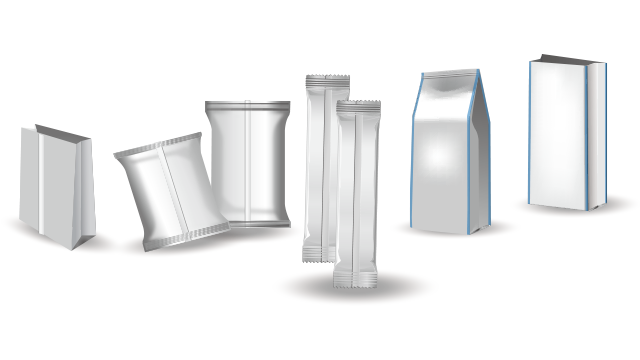

- Sealable laminated film, thickness 40-150μ.(80-150μ for Stand-up pouch and Zipper bag)

- Four kinds of bags: 3-side-seal bag, stand-up pouch, 3-side-seal bag with zipper, and stand-up pouch with zipper.

- 3-side sealed bags can be made in 3-lane operation within maximum parent-web width.

- Stand-Up pouches and zipper bags can be made in 2-lane operation within maximum parent-web width.

- Main Drive & Feeding Motor

-

- Main drive servo motor with driver provide accurate sealing time control, suitable for constant sealing time control system.

- Two sets of servo motors and drivers, to control the production speed and provide accurate bag length control.

- Feeding Motor

-

- Equipped with two sets of servo motors and drivers, which can raise the production speed and provide accurate bag length control

- Unwinding Section

-

- Horizontal type unwind stand / Swing-out/Lift-up type mechanical shaft with 3" adapters makes loading and unloading more convenient.

- Equipped with Automatic Tension Controller (diameter calculating type), provide constant and stable web tension control.

- Equipped with Line/Edge Position Controller (LPC), provide accurate bag sealing and trimming position.

- Upgraded dancer-roller provides stable tension for films before entering the bag making section.

- Two bottom-gusset-unwinding devices are equipped with motors and position detectors, which can provide stable feeding speed and tension.

- Bag Making

-

- ABM-74SPZ can make four kinds of bags: 3-side-seal bag, stand-up pouch, 3-side-seal bag with zipper, and stand-up pouch with zipper.

- 3-side sealed bags can be made by 3-lanes operation within maximum parent-web width.

- Stand-Up pouches and zippers bags can be made by 2-lanes operation within maximum parent-web width.

- Equipped with two sets of servo motors and drivers, which can raise the production speed and provide accurate bag length control.

- Equipped with Ultrasonic Welder, the zipper (in the side-sealed position) can be welded and flattened perfectly, solve the leakage problem.

- Equipped with skip operation system, the maximum bag-length could be extended. (skip-times: as request).

- Equipped with automatic lift-up mechanism to lift up the upper sealing stands and bars to avoid overheating the material when the machine stops.

- The design of safety cutter provides extra safety for the operator.

- Maintenance

-

- Equipped with covered bearing, which is unnecessary for lubrication, prolong the parts life and makes maintenance easier, faster and cleaner.

- Computer Control Operation with Touch-Screen

-

- Maintain a constant sealing time, which may largely reduce test-run scraps. When the machine speed is changed, it is not necessary to adjust temperature of the heater.

- Touch-screen makes operation easier and faster.

- Built-in Sealing Temperature Controller.

- Auto alarm/Stop available for abnormal condition.

- Alarm messages are displayed on the screen.

- Modem interface available for remote maintenance.

- Data base for saving 100 sets of working parameters.

- Operation and maintenance procedures and parameters are memorized in the computer control system for easy setup or review.

- Optional Accessories

-

- Unwind 3"/6" airshaft

- Pneumatic loading device (in unwind section)

- 6" air chuck

- Vertical/horizontal 2nd unwind stand

- Various puncher

- Conveyer

- Round corner cutter

- Various stacking systems

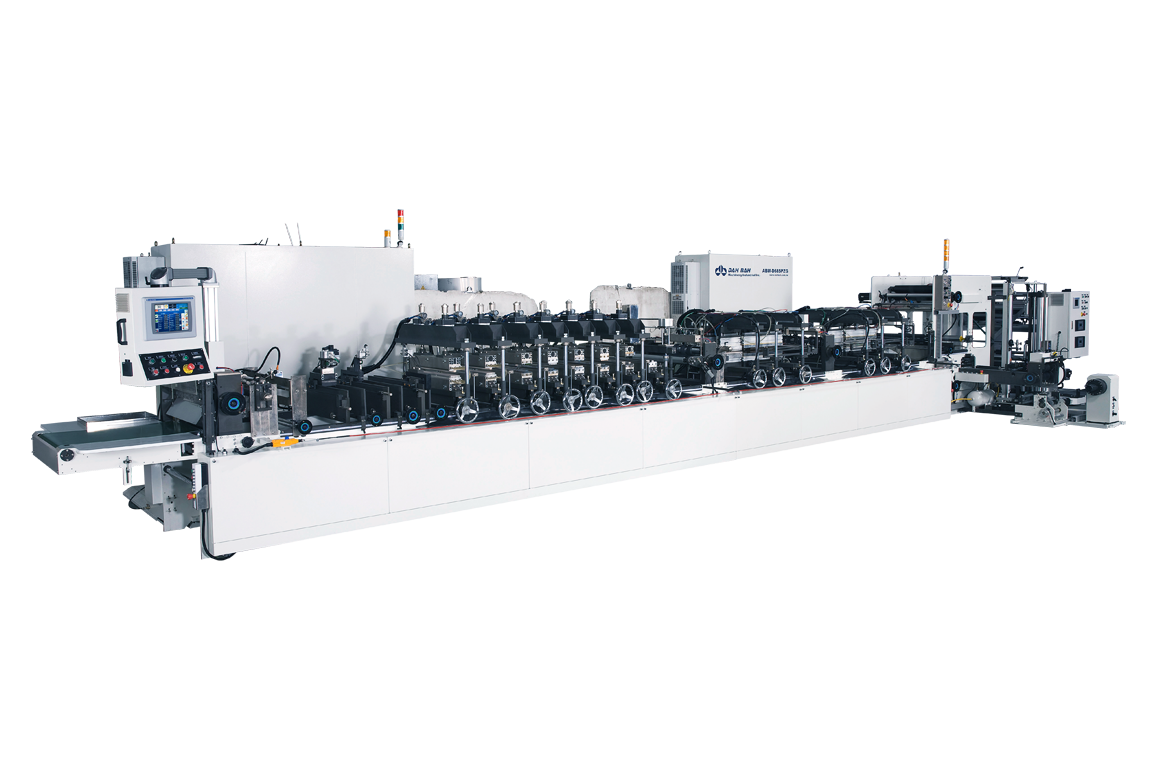

Dah Bah’s Advanced Stand-Up and Zipper Bag Making Machine is designed to produce eco-friendly, high-performance packaging such as moisture barrier bags, box pouches, and reusable packages for food, pet food, cosmetics, and other dry goods or powder products. This versatile zipper bag machine meets the needs of sustainable packaging with advanced features for precision sealing and high-speed production.

Flexible Material Handling and Feeding

-

First and Second Unwind Stands (Optional Second Unwind Stand) (H3)

The machine includes a standard first unwind stand and an optional second unwind stand, allowing flexibility in feeding both primary and secondary materials, such as bottom strips or additional layers for stand-up pouches. This versatility enhances the zipper pouch machine’s ability to handle a range of packaging formats.

-

Bottom Strip Unwind Stand

A dedicated bottom strip unwind stand ensures precise feeding for stand-up pouches, keeping material alignment accurate for consistent, high-quality output.

-

Precise Alignment with Dual Web Line Controllers

Top and bottom web edge position controllers enable precise film alignment, minimizing waste and improving overall production quality.

Advanced Sealing Technologies

-

Longitudinal Sealing Station

This station efficiently seals along the length of the pouches, offering secure, durable seals ideal for food packaging and moisture-sensitive products.

-

Ultrasonic Zipper Sealing

Ultrasonic welding technology ensures a strong, leakproof seal for zippers, improving the overall appearance and functionality of the finished bags.

-

Adjustable Sealing Stations

Customizable settings for sealing temperature, time, and pressure provide versatility, allowing the zipper bag machine to adapt to various materials and packaging types.

Intelligent Control and Safety Features

-

Touch Screen Interface

The intuitive touchscreen panel simplifies operations by allowing quick adjustments for bag length, sealing parameters, and alignment. It also stores up to 100 job presets for faster changeovers, streamlining the production process on this advanced zipper pouch machine.

-

Automatic Film Alignment and Fail-Safe Alarms

Automatic film alignment ensures smooth production, and fail-safe alarms alert operators to any misalignments or sensor failures, minimizing downtime.

-

Emergency Stop and Safety Features

Equipped with a safety-focused emergency string pull, the machine can be quickly halted to protect both operators and materials, ensuring smooth and secure operations.

The Dah Bah Advanced Stand-Up and Zipper Bag Making Machine is the perfect solution for manufacturers looking for high-performance packaging solutions with precise sealing and versatile functionality. Whether you're producing food, pet food, or cosmetic packaging, this zipper pouch machine delivers moisture-resistant, durable seals and streamlined production processes.

Ready to elevate your packaging efficiency? Contact us today to see how this zipper bag machine can optimize your production line.

| Model No. | ABM-D68SPZG | |

|---|---|---|

| Max. Parent Web Width | 600 mm | |

| Max. Parent Web Diameter | 650 / 800 mm | |

| Bottom Web Width | 60 ~ 120 mm | |

| Max. Bottom Web Diameter | 420 mm | |

| Max. Machine Speed |

160 Cuts / min. (For 3-Side-Seal Bag) 100 Cuts / min. (For Stand-Up Pouch/ Zipper Bag) |

|

|

Installation information (Standard specificatio) |

Net weight | 6680 kg |

| Area required | L 13300 x W 4700 x H2100 (mm) | |

| Power | 380V / 46KW / 84A | |

| Water | 15 - 20 ℃ | |

| Air | 6 kg / cm3 | |

Food

Steam

Frozen

Rice

Clothes

Mask

Liquid

Antistatic