- application & materials

-

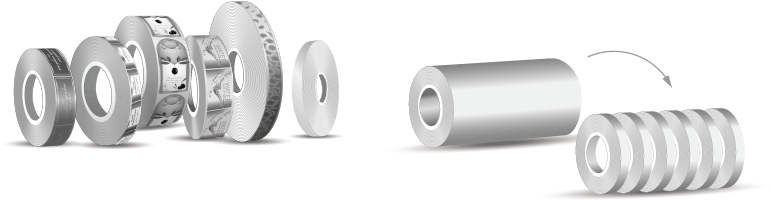

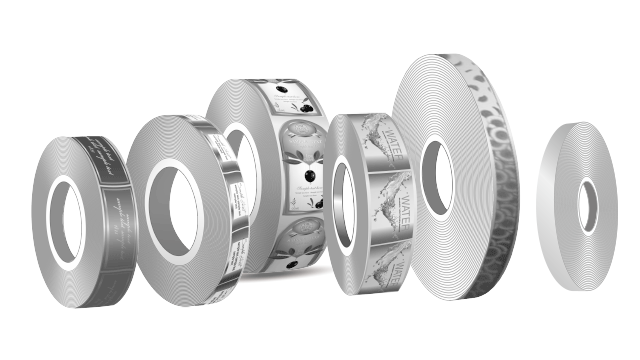

- Thermal transfer ribbon, PET

- rewinding type

-

- Center rewinding with duplex rewind-shafts.

- unwinding section

-

- Equipped with swing-out/lift-up compatible type mechanical shaft with φ3" adapters

- unwinding tension control

-

- Equipped with automatic tension controller and load-cells. The actual tension is digitally displayed, increasing the tension control precision with minimal operation effort.

- wrapping film joint device

-

- Equipped with splicing device for packaging with automatic web return function (controlled by PLC). Make almost no waste when splicing and packing. Lower down the cost and raise your efficiency.

- Equipped with splicing table with pneumatic press-bar for easy operation.

- Equipped with auto-counter, automatically positioning and packing after splicing.

- slitting section

-

- Equipped with two sets D.C. TQ motors to provide constant tension. Rewind tension gain is also adjustable.

- Equipped with automatic rewinding shafts shifting turrets (2 sets), which can largely save the loading and unloading time.

- Equipped with lift-up type mechanical rewinding shaft (1"), suitable for various size of rewinding cores.

- rewinding tension control

-

- Special rewinding tension control system, suitable for the rewinding hardness characteristic of Thermo-transfer-ribbon, Easy operation.

- The pneumatic control system for lay-on rollers for pressing the finish rolls, is adjustable to meet different materials' requirements.

- trimmed waste

-

- Equipped with blower and expulsion tube.

- optional accessories

-

- Unwind hydraulic loading device (with shaft)

- Unwinding/rewinding airshaft φ3"/6"

- φ6" air chuck

- Shaftless unwind-stand (Electrical left/right moving)

- Unwind shaftless hydraulic loading device (Hydraulic up/down, left/right moving)

- Special razor holder for slit-width less than 20mm

- Razor blade / Magnetic-fixing type razor holder

- Mechanical shaft for different sizes rewinding core

| Model No. | SLF-R100TT |

|---|---|

| Applicable material | Thermal transfer ribbon, 6~12μ |

| Max. parent web width | 700~ 1000 mm |

| Max. parent web diamete | 650 mm |

| Max. rewind diameter | 40~220 mm |

| Min. slit width | 90 mm |

| Max. machine speed | 200 m/ min. |

Ribbon