- Application & Materials

-

- Heat-sealable PP、BHDPE、BLDPE、BLLDPE tubes (for heat-sealing) or regular plastic films (for slitting).

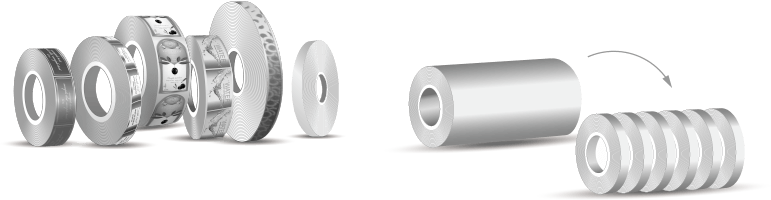

- Rewinding Type

-

- Differential center rewinding with duplex rewind-shafts.

- Unwinding Section

-

- Equipped with swing-out/lift-up compatible type mechanical shaft with φ3" adapters.

- Equipped with edge position control (EPC) to provide accurate slitting position.

- Unwinding Tension Control

-

- Equipped with automatic tension controller (diameter-calculating type) to provide stable tension and easy operation.

- Slitting Section

-

- Pneumatic controlled heating knife with automatic temperature controller ensure consistent sealing quality during high speed running.

- Equipped with razor-cutters, so that this machine can be used as a slitting machine.

- Static eliminating device equipped.

- Equipped with automatic counter which will stop the machine when reaching the pre-set length.

- Rewinding Section

-

- Swing-out type rewind stands for easy operation.

- Equipped with 3" bakelite collars for irregular thickness material

- Equipped with banana roller for film expanding.

- Equipped with lay-on rollers.

- Rewinding Tension Control

-

- Manual tension control.

- The rewind tension results from double friction of bakelite collars and powder clutches, which can make the tension of each roll regular.

- Trimmed Waste

-

- Equipped with expulsion tube.

- Optional Accessories

-

- Unwind hydraulic loading device (with shaft)

- Unwinding airshaft φ3"/6"

- φ6" airchuck

- Shaftless unwind stand(Electrical left/right moving)

- Line position control (LPC)

- Unwind/rewind automatic tension controller with load-cell

- Trim rewinder with speed synchronizing system

- Heat-sealing cutter

- razor blade/cutter holder

- Unloading device

| Model No. | SLF-HS100 | |

|---|---|---|

| Max. parent web width | 1000 mm | |

| Max. parent web diameter | 600 mm | |

| Thickness rang | 15~120 μ ( Depends on various materials' conditions ) | |

| Max. rewind diameter | 400 mm | |

| Min. slit width | 50 mm ( Depends on various materials' conditions ) | |

| Unwind/rewind core I.D. | 3" ( Or as request ) | |

| Max. machine speed | 200 M/min. | |

|

Installation information (For 1000mm standard machine) |

Net weight | 2800kg |

| Area required | L 1390 x W2350 x H1410 (mm) | |

| Power | As request | |

| Air | 6kg/cm 3 | |