Selecting the Perfect Bag Making Machine for Your Business

In the modern packaging industry, selecting the right bag making machine is a crucial investment that directly impacts your production efficiency, product quality, and market competitiveness. This guide serves as your strategic framework, exploring mainstream machine types and their core applications to help you make the most informed purchasing decision.

Why Choosing the Right Bag Making Machine is Crucial

Viewing your bag making machine as a strategic asset, not merely a production tool, is key to long-term success. The right equipment creates critical value in three core areas:

-

Seize Market Opportunities and Enhance Competitiveness

A high-performance, flexible machine enables you to swiftly adapt to diverse market demands for various bag types, driving growth and securing a competitive edge.

-

Optimize Operational Costs and Ensure Product Quality

A superior machine reduces your Total Cost of Ownership (TCO) through greater efficiency and less waste, while automation guarantees consistent, high-quality output. For example:

◎In food packaging, a high-performance machine ensures airtight seals that preserve freshness and extend shelf life.

◎In retail, it supports diverse bag designs and high-quality printing that enhance brand presentation and attract consumers.

◎In industrial applications, precise sealing and durable materials ensure packaging withstands heavy handling and transport.

-

Ensure Long-Term Value and Future-Proof Your Investment

Long-term value is secured through reliable operation, robust manufacturer support, and future-proof features like broad material compatibility and modular upgrade options.

Common Types of Bag Making Machines

-

Side Weld Machine

Forms bags by sealing and cutting the sides of center-folded film. It is an ideal high-speed, cost-effective solution for retail flat bags and carrier bags. -

Bottom Weld Machine

Uses tubular film to create an exceptionally strong, waterproof bottom seal, making it perfect for heavy-duty bags for products like soil and grains. -

High-Speed T-Shirt Bag Machine

Engineered for large-scale, high-speed production of T-shirt bags, with a single-line output of 300 to 500 bags per minute. It is a core asset for mass-production markets. -

Fin Seal / Center Seal Machine

Commonly used in Vertical Form Fill Seal (VFFS) lines, its vertical seal provides a highly airtight closure, crucial for products requiring a long shelf life, such as snacks, coffee, and pharmaceuticals. -

Special Pouch / Stand-Up Pouch Machine

Specializes in producing high-value-added formats like stand-up pouches, zipper pouches, and flat-bottom pouches. These machines focus on enhancing shelf appeal, consumer convenience, and creating premium packaging. -

Medical Bag Making Machine

Utilizes medical-grade sterilizable materials like Tyvek® to produce sterile -

medical packaging. It can manufacture diverse, high-quality pouch formats, such as self-sealing and reinforced header bags, to meet the strictest medical standards.

-

Anti-Static Bag Making Machine

Designed for the electronics and semiconductor industries, this machine produces anti-static and electrostatic discharge (ESD) bags. These bags are essential for protecting sensitive components such as semiconductor wafers, circuit boards, and precision devices from static damage during storage and transportation. They ensure compliance with strict industry standards for product safety and reliability.

The Six Key Decision Points for Purchasing a Bag Making Machine

To ensure your investment yields maximum returns, these six key factors will guide you through a comprehensive and precise evaluation.

1.Production Needs Analysis

Precise procurement begins with quantified production needs. Turning capacity, material, and specification targets into data is fundamental to ensuring the equipment meets both current and future growth. You may consider:

-

Capacity Needs: Assess current and future (3-5 years) capacity targets (bags/minute) and allow for expansion.

-

Material Compatibility: Verify that the machine can reliably process your specified film types and thickness ranges.

-

Specification Diversity: Review the range of bag sizes the equipment can produce to ensure future product development flexibility.

2. Budget and Return on Investment (ROI)

A successful investment focuses on long-term value, not short-term price. The equipment should be viewed as a profit-generating asset by evaluating its Total Cost of Ownership (TCO) and ROI over its entire lifecycle. Consider:

-

Initial Investment: Set a reasonable capital expenditure budget based on your company's financial standing.

-

Long-Term ROI: Evaluate the combined benefits of the equipment in reducing waste, saving labor, and increasing production value.

3. Machine Dimensions and Factory Layout

Practical space planning is a prerequisite for efficient equipment operation. A precise assessment of factory space and integration with existing production workflows is an indispensable step before purchase. Evaluate the following:

-

Machine Dimensions: Confirm the equipment's dimensions and allocate sufficient space for operation and maintenance.

-

Process Integration: Plan for the seamless integration of the new machine with pre- and post-production processes like printing and packing to maximize line efficiency.

4. Automation and Industry 4.0 Readiness

In the era of Industry 4.0, a machine's "intelligence" is as important as its mechanical performance. It directly determines production efficiency, quality stability, and your company's future competitiveness. Key factors to evaluate:

-

Core Control Systems:

-

Servo Motors: Ensure precision in cutting and film feeding during high-speed operation.

-

PLC and HMI: Provide an intuitive graphical interface that simplifies operation, setup, and troubleshooting.

-

Smart Features (Industry 4.0):

-

Data Analytics: Optimize production decisions through real-time data monitoring.

-

Predictive Maintenance: Warn of potential failures in advance to prevent unplanned downtime.

-

Remote Service: Accelerate problem diagnosis and resolution, reducing downtime.

5. Operability and Long-Term Reliability

A machine's true value is demonstrated in its long-term, stable operation. Superior hardware must be paired with user-friendly operation and reliable support to transform the investment into sustained productivity. Consider these key aspects:

-

Ease of Use: An intuitive interface and simplified changeover processes lower the operational skill barrier and reduce errors.

-

Ease of Maintenance: Good mechanical design should facilitate routine maintenance and come with a clear maintenance plan.

-

Technical Support and Spare Parts: Prompt technical support and a reliable supply of spare parts are critical for maintaining high operational efficiency.

6. Choosing a Reputable Manufacturing Partner

A purchase is not just a transaction; it's the beginning of a long-term partnership. An outstanding manufacturing partner should offer a comprehensive commitment covering technology, service, and future development. When evaluating, we recommend establishing objective criteria:

-

Company History and Industry Reputation

-

International Quality Certifications and Patented Technologies

-

Extensive Customer Success Stories

-

Responsiveness and Quality of After-Sales Service

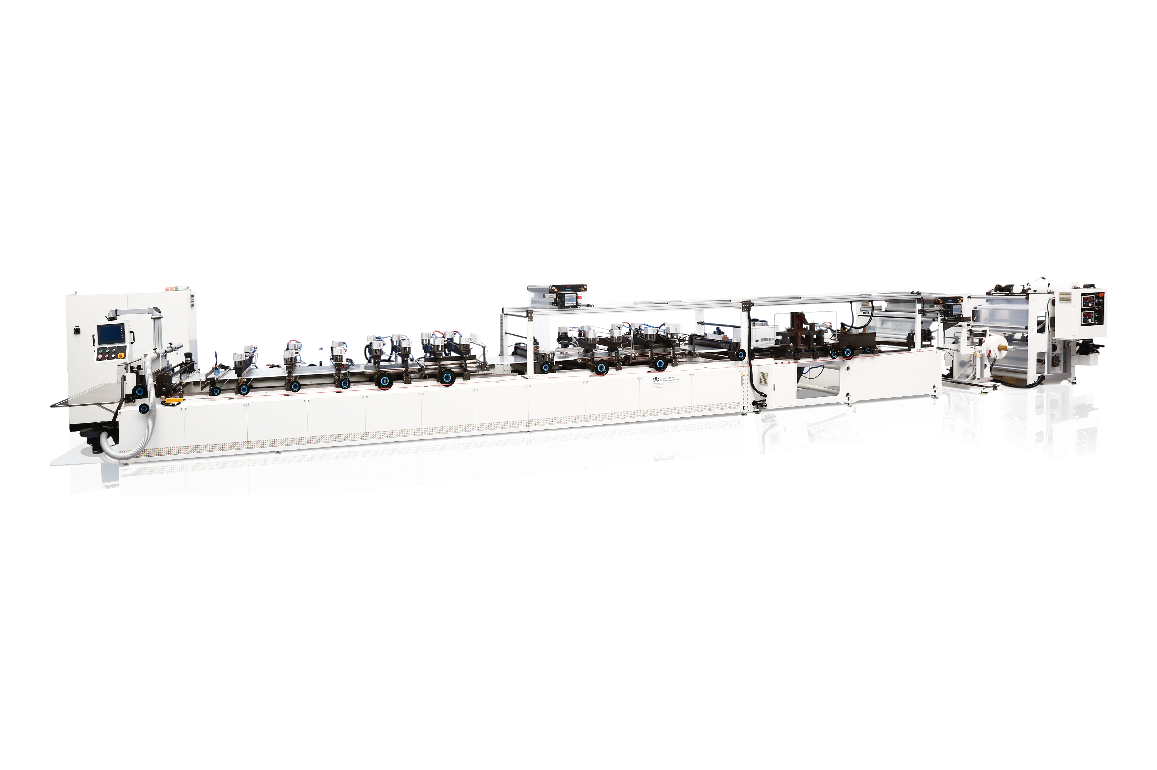

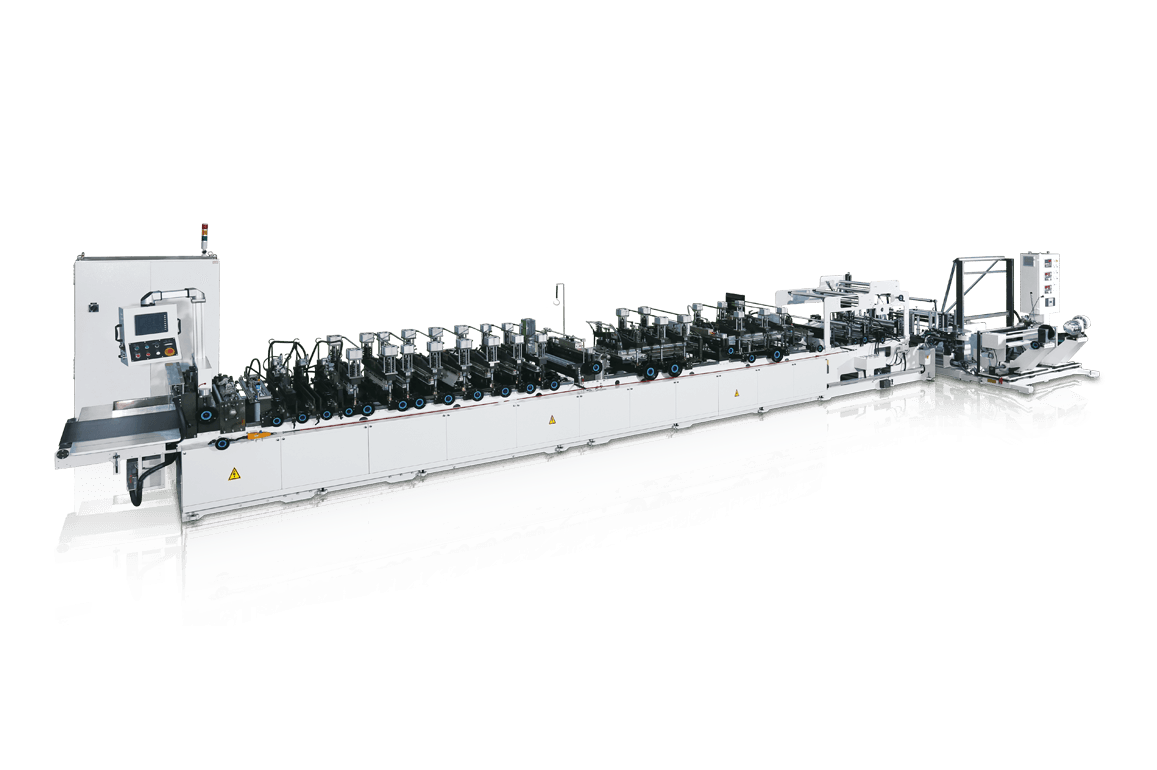

Dah Bah Machinery builds high-quality flexible packaging equipment, featuring a diverse range of ISO and CE certified bag making and slitting machines. Fully equipped with precise servo controls and advanced automation, Dah Bah's technology and reliability make it the optimal strategic partner for enhancing production efficiency and competitiveness.

FAQ

Q1: How can smart automation maximize efficiency?

A: Peak performance and quality are achieved by integrating three key automation modules that work together to eliminate bottlenecks and minimize downtime:

-

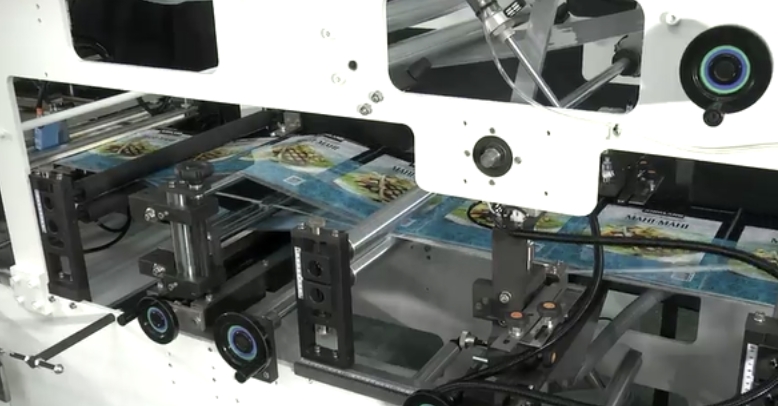

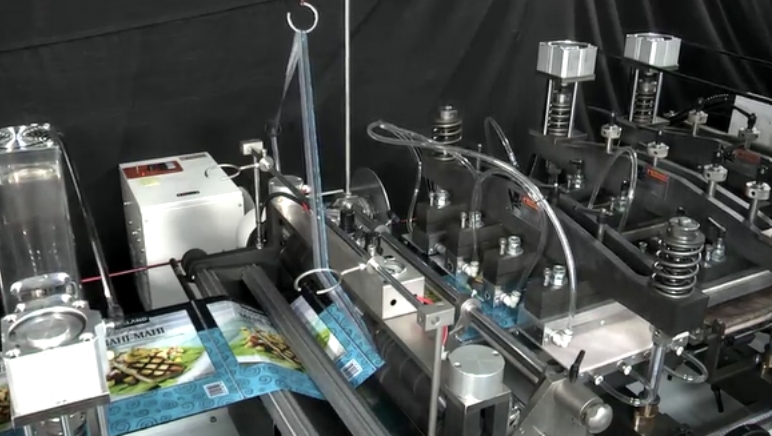

Non-Stop Unwinding System: Eliminates downtime from roll changes by splicing new film without stopping the machine, significantly boosting Overall Equipment Effectiveness (OEE).

-

Automated Splice Detection: Identifies and automatically rejects bags at film splices to ensure consistent product quality and appearance.

-

In-Line Finished Product Inspection: Uses vision systems for 100% real-time inspection of every bag for seal, dimension, and print defects, automatically removing any non-conforming products.

This integrated approach advances the production line from simple automation to autonomy, a cornerstone of modern "lights-out" manufacturing.

Q2: Can bag making machines be customized for unique bag designs?

A: Yes, many manufacturers like Dah Bah Machinery offer customization for bag sizes, shapes, and features like spouts or zippers to meet specific needs.

Conclusion

Choosing the right bag making machine is a strategic investment. To ensure long-term competitiveness and profitability, your evaluation must look beyond initial specifications to consider Total Cost of Ownership (TCO), future scalability, and the manufacturer's support capabilities.

If you have medical-grade demands, Dah Bah Machinery's AMM-83F is a professional four-layer header bag medical pouch machine. Designed specifically for the medical industry, it produces high-quality packaging that meets strict medical standards, suitable for both heat-sealable films and paper materials.