Guide to Plastic Pouch Making Machine: Process and Applications

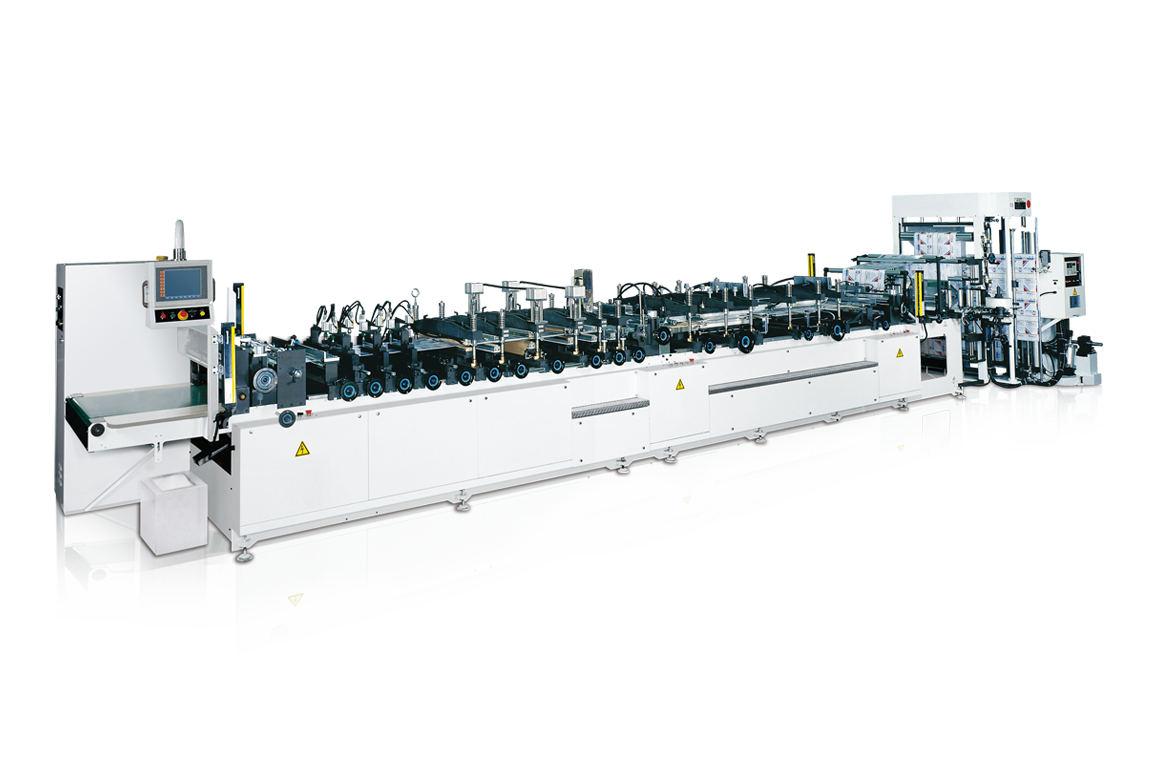

Plastic pouch making machines are specialized automated systems designed to transform plastic films into high-quality pouches with precise sealing, cutting, and forming. They are essential in modern packaging lines, producing formats such as stand-up pouches, zipper pouches, flat-bottom pouches, and medical-grade pouches.

This guide will help you understand what a plastic pouch making machine is, the main types available, the production process, and its applications—while highlighting Dah Bah’s technical strengths and tailored solutions.

What is a Plastic Pouch Making Machine?

A plastic pouch making machine is a specialized automated system designed to convert plastic films into finished pouches with precise shapes, seals, and functional features. Unlike general bag making machines, which produce a broad range of bags, pouch making machines focus on high-value formats such as:

-

Stand-up pouches

-

Zipper pouches

-

Flat-bottom pouches

-

Center-seal pouches

-

Spouted pouches

-

Medical-grade pouches

-

Anti-static pouches

These machines integrate cutting, folding, heat sealing, and optional component insertion (e.g., zippers, spouts) to produce pouches that meet strict standards for barrier protection, hygiene, and visual appeal—critical for food, medical, high-end technology products, such as wafers and premium consumer products.

Main Types of Plastic Pouch Making Machines

1. Multi-Function Stand-Up & Zipper Pouch Machines

Designed to produce stand-up pouches, zipper pouches, three-side seal pouches, and four-side seal pouches from single or multiple film layers. Features often include dual unwind stands, servo motors for precise feeding, ultrasonic zipper sealing, and advanced tension control systems. Ideal for packaging coffee, snacks, powders, and other retail products.

For specialty pouches, Dah Bah Machinery's ABM Series stands out with its ultrasonic welding for zipper applications, creating a flat, clean seal that not only improves aesthetics but also guarantees leak-proof performance. It's particularly well-suited for high-quality coffee bags, snack pouches, and powder packets.

2. Three-Side Seal & Gusseted Pouch Machines

Capable of producing three-side seal pouches, gusseted bags, and flat-bottom pouches. Equipped with adjustable bottom gusset formers, edge guiding, multiple servo drives, and reliable sealing and cooling systems to ensure consistent pouch quality.

3. Medical Pouch Making Machines

Specialized machines designed for sterile medical supplies packaging. They manufacture individual pouches, self-adhesive bags, side-seal tubular pouches, gusseted bags, and reinforced header pouches. These machines support processing of medical-grade films such as Tyvek® and other heat-sealable materials, meeting strict sanitary standards.

For example, Dah Bah Machinery's medical bag making machine, AMM-DS Series specializes in producing individual and self-adhesive pouches, the AMM-RU Series produces side-seal tubular pouches, and the AMM-83F Series is for reinforced header bags.

To complement pouch production, additional supporting equipment such as slitting machines, roll rewinding and inspection machines, spout inserting and sealing machines, and automatic valve or tin-tie sealing machines are commonly integrated into production lines

Core Advantages of a Plastic Pouch Making Machine

-

Increased Production Efficiency and Lower Costs

Automated plastic pouch making machines enable high-speed, continuous sealing and cutting with precise control, significantly reducing manual labor and production downtime. They support recyclable and biodegradable films, helping lower raw material costs and align with sustainability goals. -

Improved Product Packaging Quality and Appeal

Advanced servo control combined with three-stage heat sealing and cooling ensures every pouch has consistent dimensions, strong seals, and an attractive finish. High-quality printing and die-cut pouch designs enhance brand presentation and shelf impact. -

Reduced Material Waste

With precise tension control, servo-driven feeding, and advanced web guiding systems that maintain perfect film alignment, these machines minimize scrap rates and maximize material utilization. -

Support for Diverse Packaging Designs

Multi-functional pouch making machines produce a variety of pouch formats—including stand-up pouches, zipper pouches, and spouted pouches—with highly customizable features such as hang holes, spouts, and zipper placements to meet specific market needs.

Plastic Pouch Manufacturing Process

The manufacturing of plastic pouches is a precise and highly automated process, primarily involving the following stages:

-

Film Preparation

Plastic films (PE, PP, laminated, or multi-layer barrier films) are prepared with necessary additives to meet product protection requirements. -

Printing & Slitting

Films are printed with brand graphics using flexographic or gravure methods, then slit into precise widths suitable for pouch formats. Dah Bah offers high-precision slitting machines and rewinders to ensure superior cutting quality. -

Lamination & Curing

Multiple film layers are laminated to improve barrier performance, mechanical strength, and visual appearance, followed by curing to stabilize the structure. -

Pouch Forming & Sealing, The pouch making machine folds, seals, cuts, and optionally attaches zippers, spouts, or other features. Dah Bah uses an advanced three-stage heat sealing and one-stage cooling design to ensure seal strength and aesthetics.

-

Quality Inspection & Packaging

Finished pouches undergo automated inspection, counting, stacking, and packaging for shipment.

Applications of Plastic Pouch Making Machines

Plastic pouch making machines serve a wide range of industries requiring flexible, durable, and attractive packaging solutions:

-

Food and Beverages: From fruits and vegetables bags and frozen foods packaging to liquid products, plastic packaging offers excellent freshness preservation and moisture protection.

-

Personal Care and Cosmetics: Products like lotion, face masks, and detergents are protected by well-sealed plastic packaging that ensures hygiene and convenience.

-

Medical Drugs, Pharmaceuticals and Health Products: Medical-grade packaging that meets strict sanitary standards is used to protect pharmaceuticals and medical devices, ensuring their safety and efficacy.

-

Daily Necessities: Fulfills everyday needs with shopping bags, trash bags, and storage bags.

-

Pet Food: Packaging with excellent barrier properties ensures the freshness and nutritional value of pet food.

-

Horticulture and Agriculture: Small packets for products like seeds and fertilizers provide effective moisture proofing and convenient portioning.

-

Technology and Electronics: Anti-static pouches are essential for protecting sensitive components such as semiconductor wafers and precision electronics from static discharge, humidity, and contamination.

Best Practices for Maintaining Plastic Pouch Making Machines

To ensure the long-term, efficient operation of the equipment, these three maintenance strategies are crucial:

-

Implement Daily Safe Operations and Alarm Response: Operators must strictly adhere to safety protocols and respond immediately to automated alarms (e.g., film run-out, temperature anomalies). This is fundamental to ensuring production continuity and personnel safety.

-

Adopt Smart Remote Monitoring: Using IoT technology, managers can remotely monitor the production line status via an app or a cloud-based dashboard. This allows for the immediate detection of anomalies, accelerates troubleshooting, and enables transparent, efficient factory management.

-

Practice Predictive Maintenance: By continuously monitoring equipment data, potential failures can be predicted and maintenance can be scheduled in advance. This effectively reduces unplanned downtime and maximizes equipment reliability and lifespan.

FAQ

Q1: How does Dah Bah Machinery's equipment meet the flexible production needs of different orders?

A: Dah Bah Machinery's machines are equipped with an advanced, user-friendly Human-Machine Interface (HMI) and a servo control system, featuring the following characteristics for high customization and flexibility:

-

Intuitive Touchscreen: Operators can easily set and adjust all production parameters.

-

Parameter Recipe Storage: Parameter combinations for different orders can be pre-stored and recalled with a single touch, significantly reducing changeover time.

-

Precise Servo Control: The system ensures the accuracy of sealing/cutting dimensions and temperature, regardless of changes in bag type, material, or speed.

-

High Material Compatibility: Our equipment can process a wide range of laminated or multi-layer structure materials to meet complex packaging

Q2: Besides price, what other key factors should be considered when choosing a plastic pouch making machine?

A: A wise investment goes beyond price. Evaluate these key factors:

-

Capacity and Efficiency: Assess your production volume. Decide whether you need a high-speed machine for standardized mass production or a flexible model with quick changeovers for diverse orders.

-

Bag Type & Material Compatibility: Verify the machine can handle your current and future bag types (e.g., stand-up pouches, zipper pouches) and materials (e.g., PE, laminated, recyclable materials).

-

After-Sales Support: Robust technical support, spare parts, and maintenance are crucial to minimize downtime. Dah Bah Machinery’s global service network provides immediate support to protect your investment.

Conclusion

Choosing the right plastic pouch making machine is a critical step in enhancing your product's value and market competitiveness. From production efficiency and packaging quality to design flexibility, a superior machine delivers long-term benefits. Dah Bah Machinery not only provides advanced machinery but is also committed to being your most reliable partner. We take the time to understand your needs and deliver tailor-made solutions.

If you’re looking for multi-functional stand-up and zipper pouch capabilities, the ABM-SPZ series offers a versatile solution with precise servo-driven feeding, ultrasonic zipper sealing, and a user-friendly touchscreen—ensuring both high efficiency and premium packaging results.

Contact us today for your market-leading packaging solutions.